On the factors affecting the extrusion efficiency of aluminum motor casing

2024-07-19()Views

1. Reasonable frame installation can avoid crushing, which is an effective way to improve the yield. According to the different shapes of the products, wall thickness using layered frame installation methods, increase the number of separating branches of each layer, to avoid crushing of aluminum motor shell products.

2. In the extrusion process of aluminum motor casing, choose the aluminum alloy casting bar that meets the production requirements to prevent the production of bulk waste, which is the prerequisite for improving the yield.

3. The sawing length of aluminum motor shell should be accurate, and the sizing should be accurate. When sawing each time, pay attention to the sizing stopper can not move, and the material head should be uniformly in place.

4. Standardized process operation is a powerful guarantee to improve the yield. To strictly implement the “three temperatures do not meet the standard can not be produced”, do not move the center of the mold to ensure proper start-up speed. The cutting rod is not too long to ensure that the process waste meets the specification requirements.

Latest News

-

What kind of...

In the process of motor operatio...

-

Prospects fo...

The world's major automobile com...

-

What are the...

The housing technology supports,...

-

What are the...

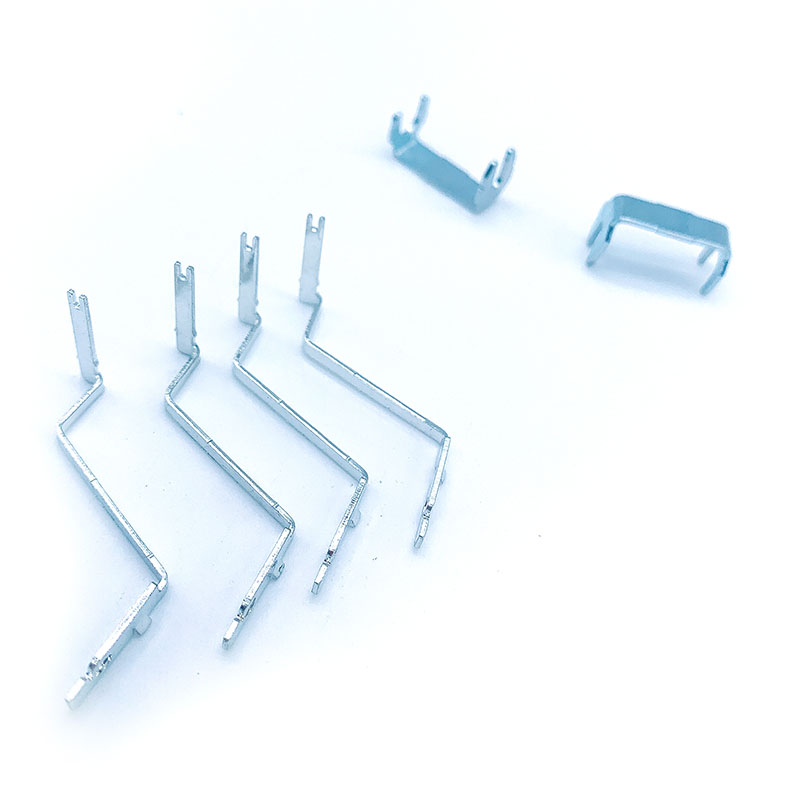

Depending on the shape of the pa...

86 159-1379-7791

Cell phone:159-1379-7791(WeChat)

Telephone:0769-39029833

Email:huqihua@hjcmotor.com

Address:Room 101, Building F3, No. 215, Yuehai Avenue, Xiegang Town, Dongguan City, Guangdong Province, China